Selecting the right PCBA (Printed Circuit Board Assembly) manufacturer is a critical decision that can significantly impact the success of your electronic products. With numerous manufacturers available, understanding key factors can help ensure you partner with a provider that meets your technical and business needs. Here, we explore essential considerations for choosing a reliable PCBA manufacturer and the advanced solutions they offer, such as Rigid-Flex and High-Frequency PCBs.

1. Technical Expertise and Capabilities

A crucial factor when selecting a PCBA manufacturer is their technical expertise. Look for a company with a proven track record in handling complex PCB projects. An experienced manufacturer should be adept at fabricating Rigid-Flex PCBs, High-Density Interconnect (HDI) boards, and High-Frequency PCBs, which are essential for applications in demanding industries like telecommunications and robotics.

Global Well PCBA, for instance, showcases its technical prowess in providing cutting-edge PCB solutions. Their capability to deliver complex assemblies ensures high performance and reliability in electronic devices.

2. Quality Standards and Certifications

Quality is paramount in PCB manufacturing. Ensure your chosen manufacturer adheres to international standards like ISO 9001, ISO 14001, or IPC-A-610. These certifications demonstrate the manufacturer’s commitment to quality and environmental management systems. High-quality PCBs reduce the risk of defects, ensuring better performance and longevity of your products.

3. Customization and Design Support

Every project has unique requirements, and a good manufacturer should offer customization options and design support. They should be able to assist in the early stages of product development, offering insights into design for manufacturability (DFM) and design for assembly (DFA). This collaboration can help streamline production processes and minimize costs.

Global Well PCBA provides extensive support throughout the design and production phases, ensuring that clients receive tailored solutions that align with their specific project needs.

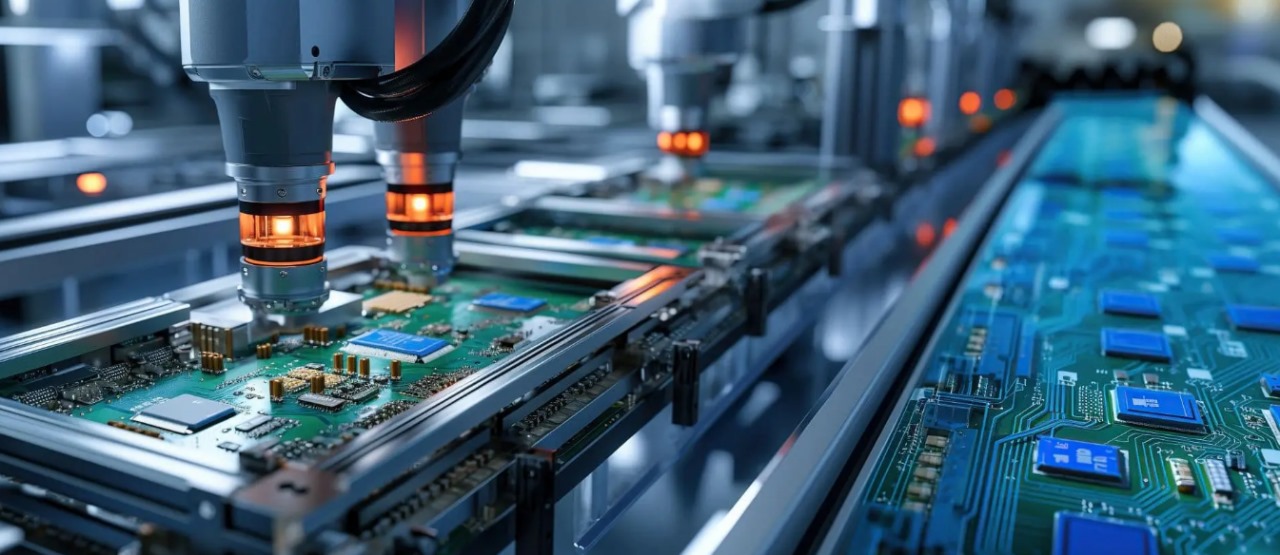

4. Advanced Manufacturing Technologies

Innovation in manufacturing technologies is essential for producing high-quality PCBs. Modern manufacturers invest in advanced equipment like automated optical inspection (AOI), X-ray inspection, and surface-mount technology (SMT) lines. These technologies ensure precision and high throughput, which are critical for industries with stringent performance requirements.

5. Supply Chain Management and Sourcing

Efficient supply chain management is vital for ensuring timely delivery of PCBs. Manufacturers with strong relationships with reliable suppliers can secure quality components and manage costs effectively. Moreover, companies with in-house component sourcing capabilities can offer better control over the production process and reduce lead times.

Global Well PCBA excels in component sourcing and supply chain management, ensuring that projects are completed on schedule and within budget.

6. Industry Applications and Expertise

Different industries have specific requirements for PCB design and manufacturing. A manufacturer experienced in sectors like telecommunications, robotics, aerospace, or automotive can provide valuable insights into industry standards and best practices. This expertise ensures that your PCBs meet the demanding requirements of your industry.

7. Cost-Effectiveness

While cost is a significant consideration, it should not compromise quality. A reliable manufacturer will provide competitive pricing while maintaining high standards. Be wary of extremely low-cost options that might cut corners, leading to quality issues down the line.

Global Well PCBA strikes a balance between cost and quality, offering competitive rates without compromising on their rigorous quality control processes.

8. After-Sales Support and Warranty

A good manufacturer should offer robust after-sales support, including technical assistance, troubleshooting, and warranty services. This support is crucial for addressing any issues that may arise post-delivery and ensures long-term satisfaction with the product.

In conclusion, choosing the right PCBA manufacturer requires careful consideration of various factors, including technical expertise, quality standards, customization capabilities, and cost-effectiveness. Partnering with a reputable manufacturer like Global Well PCBA can provide the assurance of high-quality products that meet the needs of advanced applications in industries such as telecommunications and robotics.